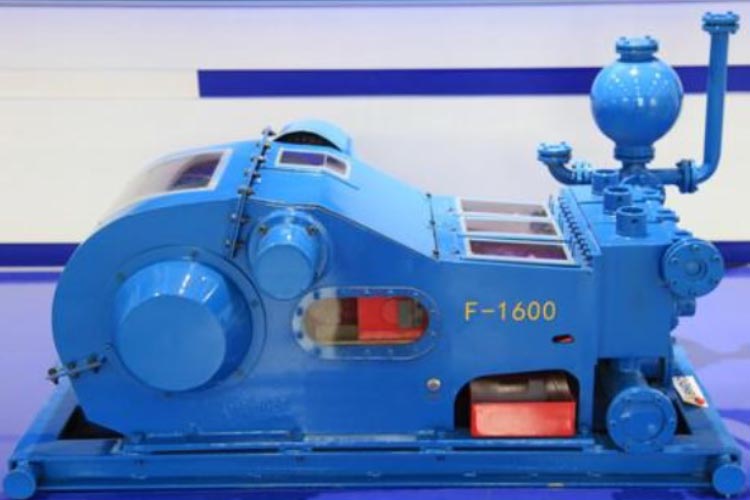

I. Drilling Mud Pumps

Mud pumps play an extremely critical role in drilling operations. Simply put, they are responsible for injecting drilling mud from the surface into the bottom of the well through the drill pipe, and then circulating the cuttings-laden mud back to the surface. While this circulation process appears straightforward, it holds multiple vital functions. At the bottom of the well, the mud cools and lubricates the drill bit, extending its service life. Simultaneously, the mud utilizes its own pressure to balance formation pressure, preventing dangerous situations such as blowouts. Additionally, it promptly transports rock fragments broken by the drill bit out of the wellbore, ensuring smooth drilling operations. It is no exaggeration to state that without the stable operation of mud pumps, drilling work would come to a standstill.

II. Working Principle of Mud Pumps

The working principle of mud pumps is based on a simple yet ingenious design. Taking the common piston-type mud pump as an example, it mainly consists of a power end and a fluid end. The power end drives the crankshaft to rotate via an electric motor or other power devices, converting the rotational motion into reciprocating linear movement of the connecting rod and piston. When the piston moves backward, a vacuum is created in the fluid end cylinder, allowing mud to enter the cylinder through the suction valve under atmospheric pressure. When the piston moves forward, the mud inside the cylinder is compressed, increasing the pressure and forcing open the discharge valve. The mud is then expelled from the cylinder and transported through pipelines into the drill pipe. This process resembles using a syringe to draw and push liquid, except that mud pumps operate on a much larger scale with higher pressure and continuous operation.

Plunger-type mud pumps are similar to piston-type pumps but use plungers instead of pistons. The sealing between the plunger and cylinder liner is superior, enabling them to withstand higher pressures, making them suitable for deep-well drilling operations with stringent pressure requirements. Diaphragm-type mud pumps utilize a diaphragm to separate the pump chamber into upper and lower sections. The reciprocating motion of the diaphragm achieves mud suction and discharge. This pump type offers excellent sealing performance and unique advantages in conveying highly corrosive mud.